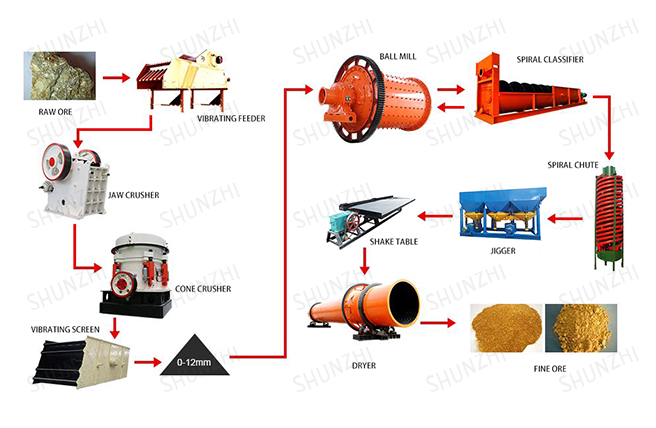

Gravity beneficiation, referred to as gravity separation, is a beneficiation method that separates minerals according to their density. In addition to the re-selection equipment, there must be a medium for reselection. Media such as water and air.

1. Remove mud by water. Under the action of water flow. Disperse the agglomerated or fine mud that is bonded with quartz grains, and remove the mud. It is suitable for removing clay fine mud from industrial sand such as glass and foundry.

2. Hydraulic classification. According to the different sedimentation speed of minerals with different particle sizes in the water flow, the wide grade group is divided into several graded products. Different grades are separated to meet user requirements, suitable for processing foundry sand, glass sand , cement standard sand, etc.

3. Shaking bed beneficiation. Iron and ore particles with high density settle faster in water; quartz grains with small density are separated from heavy minerals under the combined action of horizontal and vertical water flow. It is suitable for removing iron and other heavy minerals from glass sand.

The main process types of the gravity separation process are: classification, jigging, shaking table and spiral chute.

The re-selection process adopts.

1. Poor and rich separation, 2. Coarse and fine separation, 3. Sand and mud separation to prevent over-grinding (discard tailings or select concentrate before grinding) and other reasonable gravity separation processes, and use magnetic, Various combined processes such as heavy and flotation; in terms of mechanization, heavy medium method is used instead of manual selection, and mechanical beneficiation equipment is used instead of manual panning and other operations

1. The equipment has good stability, convenient operation and low cost. The technology is also relatively mature.

2. No precious chemicals are used in beneficiation production, and the discharged tailings have little environmental pollution.

3. It can be combined with other beneficiation methods to recover weakly magnetic minerals embedded with finer particle size.

4. Gravity separation can get better sorting index, can produce coarse concentrate or mixed concentrate, and can also get final concentrate.