Guinea Gold Mine Flotation Project is a complete design and installation project undertaken by Henan Shunzhi. The project is mainly for the manufacture and installation of the main workshop (grinding, flotation).

crushing and screening stage

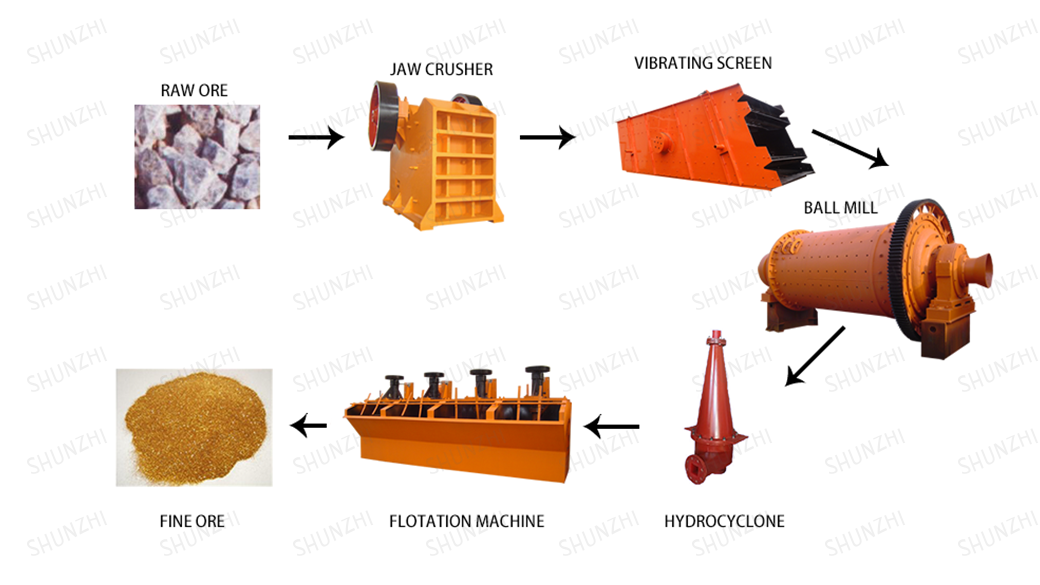

The crushing system uses the jaw crusher for coarse crushing and fine crushing. The crushed materials are fed into the ball mill in the main workshop through the belt and enter the grinding system.

Grinding and grading stage

The grinding adopts a closed-circuit grinding system composed of a ball mill and a cyclone group.

flotation stage

The flotation adopts the process of one roughing, three sweeping and four refining, respectively producing flotation gold concentrate and flotation tailings. The flotation gold concentrate is pumped into the original concentrate dewatering system, and the flotation tailings are pumped into the original tailings conveying system.

The raw ore is conveyed to the jaw crusher by the belt conveyor for coarse crushing, and the coarsely crushed material is screened by the vibrating screen and then enters the fine crusher for fine crushing.

The finely crushed materials are conveyed by the belt conveyor to the wet ball mill for grinding.

The materials ground by the ball mill are fed into the flotation system after dosing and sizing by the hydrocyclone.

The flotation adopts the process of one coarse, three sweeps and four fines. After flotation, it enters the dehydrator for dehydration.