This customer is from Mongolia. Due to geographical and policy constraints, Henan Shunzhi's technical team designed a 300t/h copper ore dressing plant after a series of careful investigations, which has been running for a long time now. The interests of our clients have increased a lot.

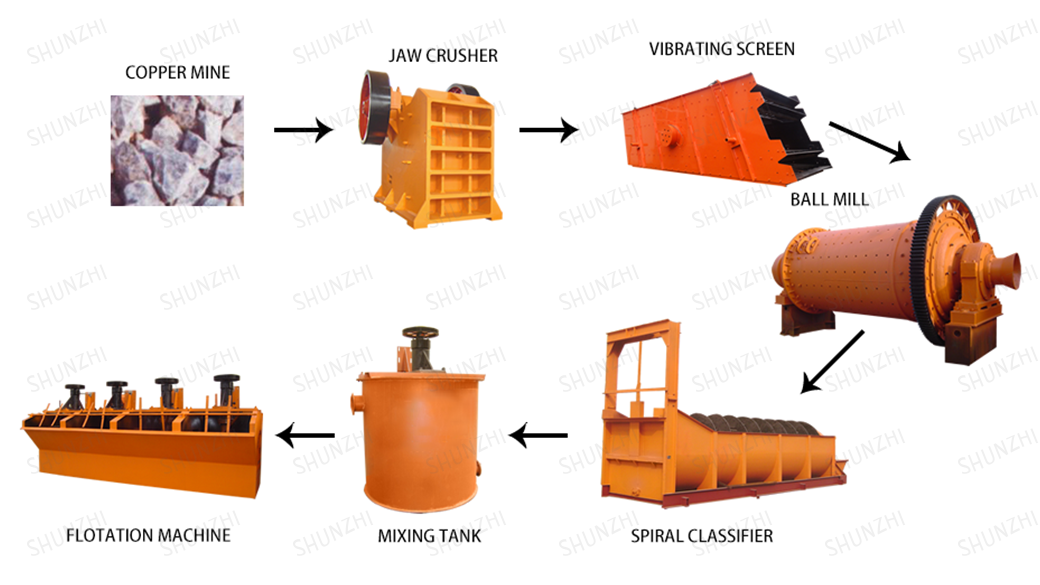

According to the natural conditions, terrain and characteristics of Mongolian copper mines, our experts designed PE jaw crusher, PEX impact crusher, ball mill, spiral classifier, flotation machine and dryer and other equipment. The processing of copper ore includes four processes: crushing, grinding, flotation and drying.

Large-scale raw ore is continuously sent to jaw crusher through vibrating feeder for primary crushing, and then enters impact crusher for secondary crushing.

The crushed ore enters the circular vibrating screen for screening. For larger crushed ore, it will be sent back to the impact crusher again for continuous crushing.

Qualified materials are sent to the ball mill for grinding.

The materials with suitable particle size processed by the ball mill are transported to the flotation machine for flotation operation.