The silver beneficiation project is contracted by Henan Shunzhi, and the main minerals are galena, white lead and barite. Other associated minerals include azurite, azurite, pyrite, lead vanadium, chalcopyrite, bornite, tetrahedrite, hematite and manganese, and gangue minerals include quartz, calcite, feldspar, mica and siderite.

Grinding and beneficiation stage

The crushed products enter the first stage of closed-circuit grinding and classification. In order to recover large-particle and high-grade lead concentrates in advance, a jigging gravity separation is added between the discharge end of the ball mill and the classifier. The concentrate is naturally precipitated and dehydrated.

Concentrate flotation stage

The overflow of the classifier enters the flotation process of one roughing, three sweeping and three refining, and the flotation concentrate goes through a two-stage dehydration process as the final concentrate.

Tailings dewatering stage

The tailings are transported to the tailings pond after dry discharge.

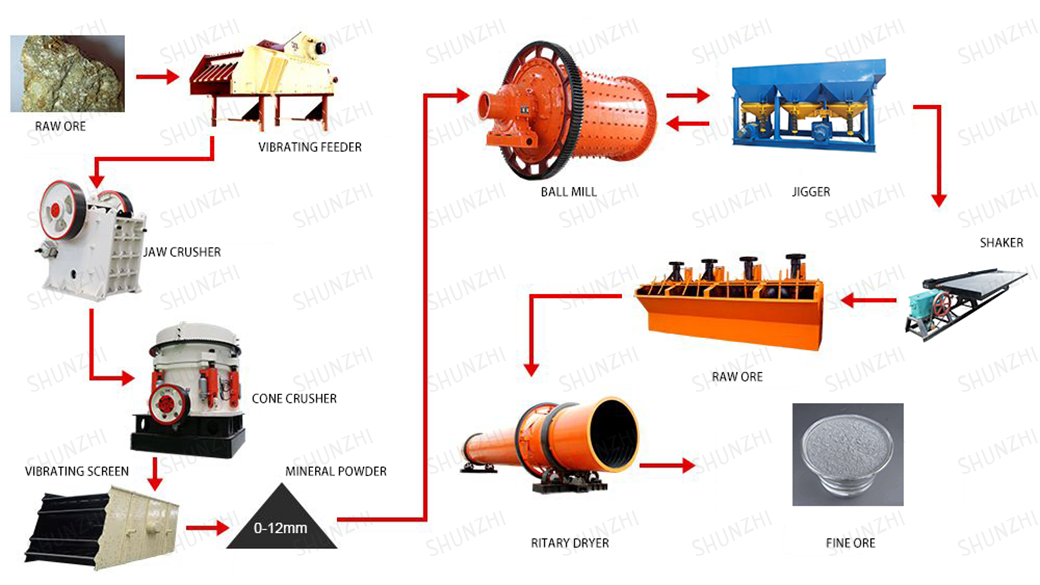

Large-scale raw ore is continuously sent to jaw crusher through vibrating feeder for primary crushing, and then enters impact crusher for secondary crushing.

The crushed ore enters the circular vibrating screen for screening. For larger crushed ore, it will be sent back to the impact crusher again for continuous crushing.

Qualified materials are sent to the ball mill for grinding.

A jig gravity separation is added between the discharge end of the ball mill and the classifier, and the jig concentrate is selected by a shaking table.