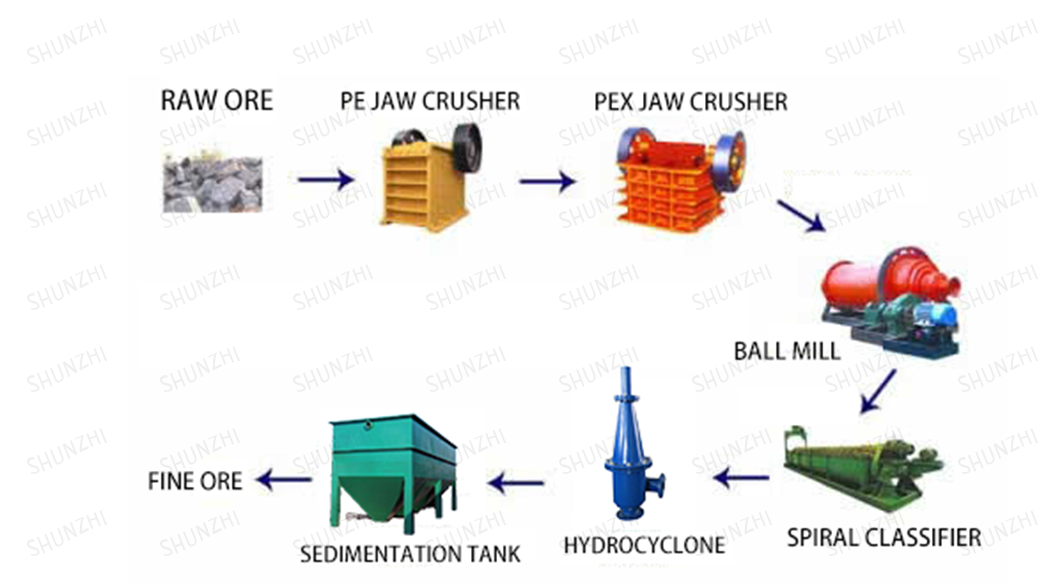

The chrome ore beneficiation project in Turkey is the whole mining industry chain service provided by Henan Shunzhi. The raw ore grade of this project is 8.53%. According to the actual situation, a two-stage-one closed-circuit crushing and screening-one-stage closed-circuit grinding and classification-gravity separation-concentrated tailings dewatering process flow is designed for it.

crushing and screening stage

The two-stage one-closed-circuit crushing and screening process is adopted, and the particle size of the final crushed product is -15mm.

Grinding and grading stage

The ball mill is used for grinding and classification, and the classification adopts a linear screen. The qualified products are classified by a hydraulic classifier again.

reselection stage

The hydraulic classifier separates two grades of pulp, +100 mesh and -100 mesh, and the two pulps enter two sets of hydraulic classifiers for gravity separation. The tailings are selected as the final tailings. The concentrate of the classifier then flows into the shaker for selection to obtain the final concentrate, and the tailings in the shaker are returned to the ball mill for regrinding.

Concentrated tailings dewatering stage

Dewatering is carried out in sedimentation tanks, and the dehydrated water is returned to the production cycle for use.

Large-scale raw ore is continuously sent to jaw crusher through vibrating feeder for primary crushing, and then enters PEX fine jaw crusher for secondary crushing.

The crushed ore enters the circular vibrating screen for screening. For larger crushed ore, it will be sent back to the fine jaw crusher again for continuous crushing.

Qualified materials are sent to the ball mill for grinding.

The two pulps enter two groups of hydraulic classifiers for gravity separation respectively, and the tailings are selected as the final tailings.