This project is a coal slag beneficiation project. The technicians of Henan Shunzhi have carried out a series of scheme designs according to the basic nature of the raw materials through field investigation, and finally determined the appropriate scheme.

The crushing system adopts two processes of coarse and fine crushing. The crushed raw ore is transported to the ball mill by the vibrating feeder. The ball mill discharges the material into the large-particle gold selection fixture, and the underflow of the jig enters the vibrating table, which can collect about 30% of the ore. Particle gold, the jig overflows back to the classifier, the classifier overflows to a stirring tank, and then enters the flotation system. The flotation concentrated flotation tailings enter the filter press respectively.

We have very strict management of each project, and each project has one person responsible from the beginning to the end, which can ensure the smooth progress of the whole process.

The design institute will start with engineering design, precise positioning technology and its products, which will not only ensure technology, but also reduce customer costs and choose the best process.

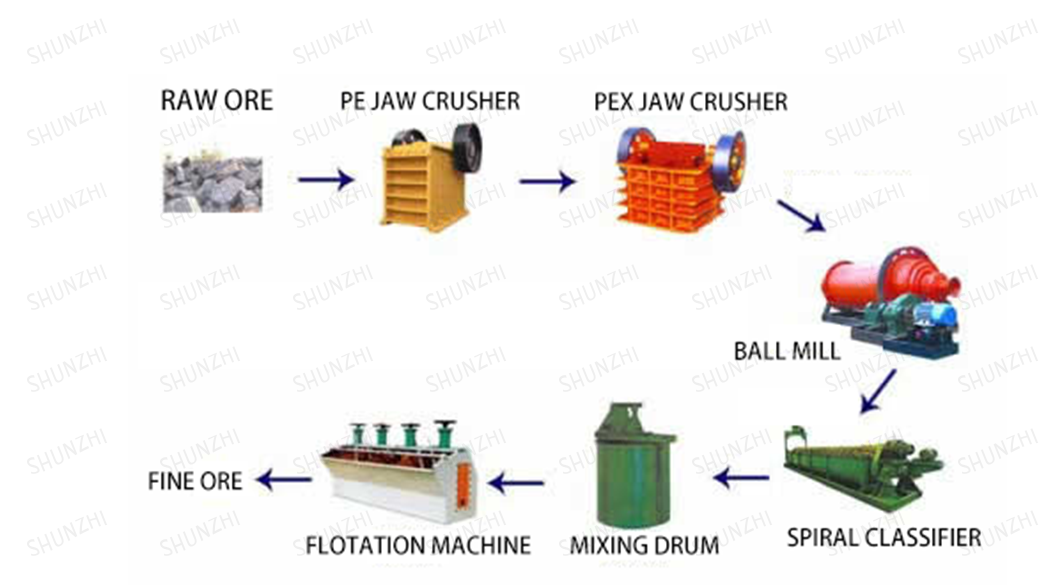

Large-scale raw ore is continuously sent to jaw crusher through vibrating feeder for primary crushing, and then enters PEX jaw crusher for secondary crushing.

The crushed ore then enters the circular vibrating screen for screening. For larger crushed ore, it will be sent back to the PEX jaw crusher again for continuous crushing.

Qualified materials are sent to the ball mill for grinding. The ground powder enters the spiral classifier for classification and washing.

The qualified mineral powder is sent into the mixing barrel, and a certain amount of medicament is added. After complete mixing and stirring, these powders will enter the flotation machine for beneficiation work.