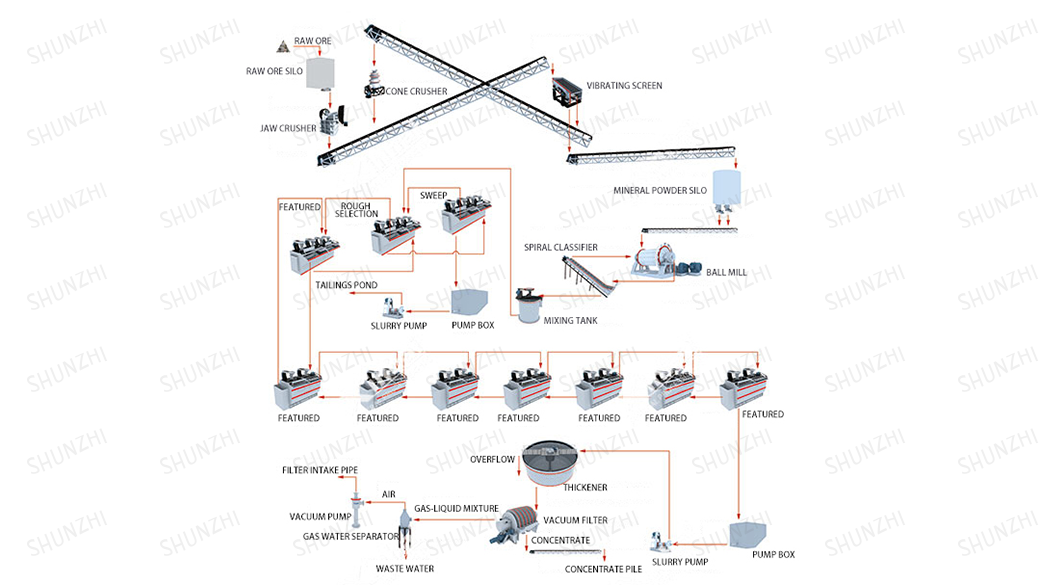

The beneficiation methods of fluorite ore are gravity separation method and flotation method. Fluorite ore beneficiation equipment is also divided into gravity separation equipment and flotation equipment. Gravity separation equipment refers to jig, and only jig can process coarse fluorite lump ore , Fluorite flotation equipment is similar to other mineral flotation equipment, including crushers, ball mills, flotation machines, etc.

The fluorite ore flotation process can be applied to the refractory fluorite ore with complex ore properties, such as high mud content in the original ore, symbiosis between impurity minerals and fluorite, and fine particle size of useful minerals.

Process method

The composition of fluorite ore is complex, and the properties of useful minerals are similar to those of gangue minerals. Generally, the combined process of flotation, gravity separation and magnetic separation is used for treatment.

Separation of Fluorite and Barite

Generally, fluorite and barite are mixed for flotation, and then separated. In the mixed flotation, oleic acid is used as a collector to obtain mixed concentrate. The mixed concentrate can be separated by positive flotation or reverse flotation to obtain fluorite concentrate.

Separation of Fluorite and Quartz

Fluorite is captured with fatty acids, and quartz is suppressed by water glass. The dosage of water glass should be properly controlled. A small amount can activate fluorite, but not enough to inhibit quartz. Excessive amount will inhibit fluorite. Sometimes in order to enhance the inhibitory effect of water glass on quartz, some polyvalent metal ions are also added, which not only inhibit quartz but also calcite.

Separation of Fluorite and Sulfide Ore

For fluorite containing sulfide ore, generally use a xanthate collector to float the sulfide ore, and then add a fatty acid collector to flotate fluorite. In the flotation operation of fluorite, a small amount of sulfide mineral inhibitor can also be added. To suppress residual sulfide minerals to ensure the quality of fluorite concentrate.

1. According to the ore composition, you can freely choose the matching model.

2. The whole system reduces energy consumption and improves recovery rate.

3. Small footprint, convenient operation and higher beneficiation efficiency.

4. The discharge material can reach the standard concentrate index, which is environmentally friendly and pollution-free.