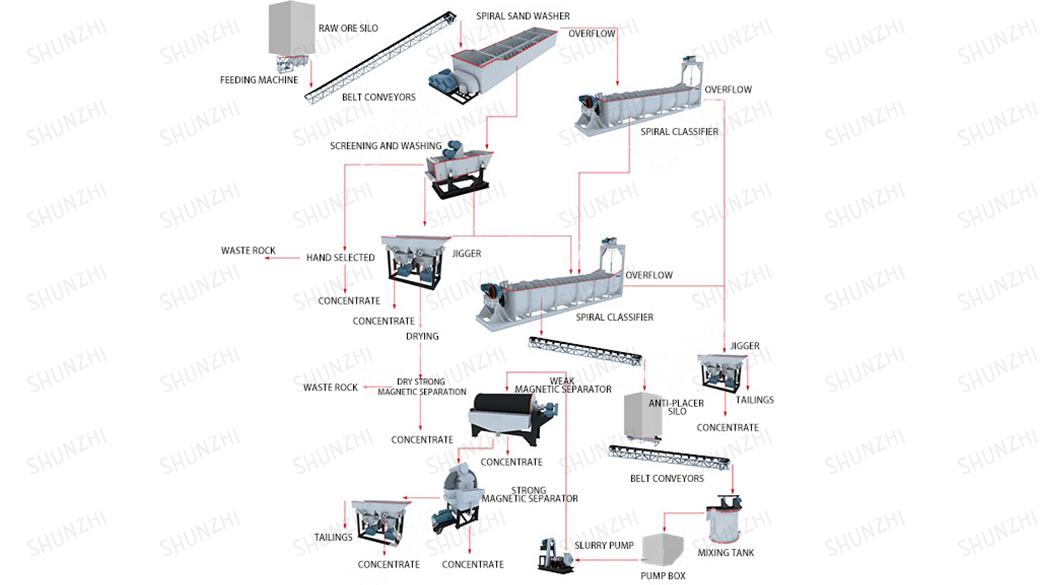

Manganese minerals are weak magnetic minerals and can be recovered by using a strong magnetic separator. In the manganese mineral beneficiation process, the magnetic separation process is mainly used, which is divided into two stages: strong magnetic roughing and medium magnetic beneficiation, which can increase the grade of manganese ore by 4% to 10%, bringing rich benefits to the beneficiation plant.

The magnetic separation process of manganese ore is suitable for separating high phosphorus, high silicon and low iron manganese ores.

Strong magnetic roughing

First of all, the impurities in the manganese ore are preliminarily removed by a special strong magnetic separator for manganese ore. The rougher concentrate is classified by a spiral classifier, and the rougher tailings are directly discharged to the tailings thickener.

Grading

The classified underflow of the classifier is sent to the magnetic separator for selection, and the classified overflow is concentrated by the concentrator.

China Magnetics Featured

The concentrated tailings of China Magnetics are discharged to the tailings thickener, and the concentrated underflow of China Magnetics is merged.

concentrate

The concentrated overflow is used to enter the return water system, and the concentrated underflow is combined with the selected concentrate to become the final selected concentrate.

1. According to the ore composition, you can freely choose the matching model.

2. The whole system reduces energy consumption and improves recovery rate.

3. Small footprint, convenient operation and higher beneficiation efficiency.

4. The discharge material can reach the standard concentrate index, which is environmentally friendly and pollution-free.