Nickel ore is mainly divided into copper-nickel sulfide ore and nickel oxide ore. The beneficiation method for processing copper-nickel sulfide ore is mainly flotation, while magnetic separation and gravity separation are usually auxiliary beneficiation methods.

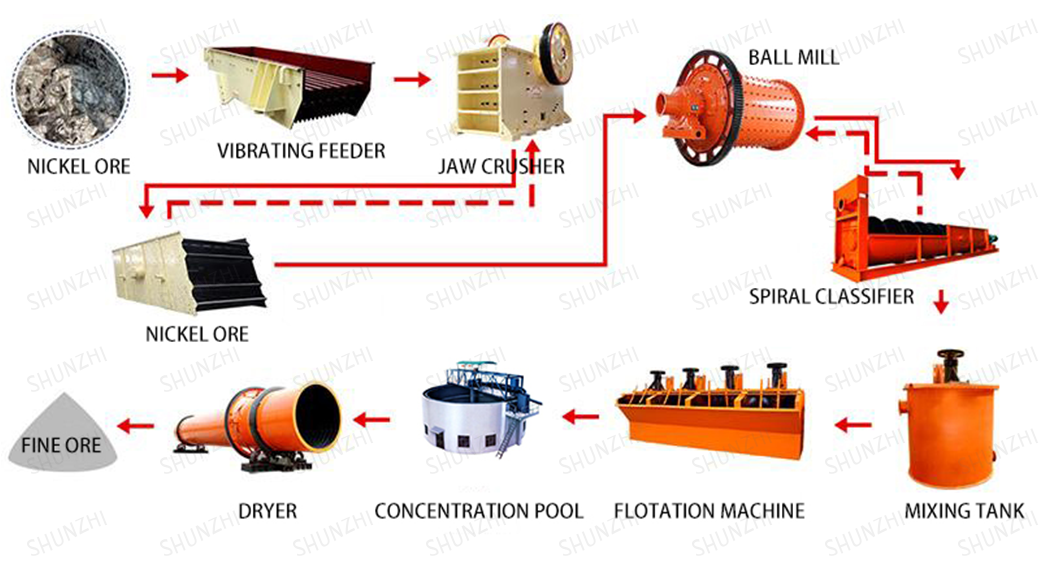

The nickel ore beneficiation process can be applied to copper-nickel ore or nickel oxide ore with pyrite and various other gangues.

Mixing - flotation process

It is used for sorting ores with lower copper content than nickel, and the obtained copper-nickel mixed concentrate is directly smelted into high nickel matte.

Mixed-optimized flotation process

The flotation of copper and nickel is mixed from the ore, and the low nickel-containing copper concentrate and the copper-containing nickel concentrate are separated from the mixed concentrate. After the nickel concentrate is smelted, high nickel matte is obtained, and the high nickel matte is separated by flotation.

Blending - preferential flotation and partial nickel recovery from blended flotation tailings

When the floatability of various nickel minerals in the ore is very different, after the copper-nickel mixed flotation, the nickel-containing minerals with poor floatability are further recovered from the tailings.

Flotation process of copper-nickel ore

In the flotation of copper and nickel sulfide ores, collectors and foaming agents for flotation of copper sulfide minerals are often used. A basic principle in determining the flotation process is to prefer copper to nickel concentrates and to avoid nickel from copper concentrates as much as possible. Because the nickel in the copper concentrate is lost in the smelting process, the copper in the nickel concentrate can be recovered more completely. When the copper content of the ore is much higher than the nickel content, the copper can be selected as a separate concentrate. The advantage of this process is that copper concentrates with lower nickel content can be obtained directly.

1. The production line process is relatively simple and the flotation time is long.

2. Fewer selections and more concentrated concentrates are scattered and selected, so that nickel minerals can be recovered as soon as possible.

3. The grade of nickel concentrate is as high as 12%, and good economic benefits are obtained.

4. Integrated production line, low cost and convenient operation.