According to different properties of phosphate rock, the beneficiation methods of phosphate rock include flotation, scrubbing and desilting; gravity separation, chemical leaching, combined beneficiation; photoelectric sorting, magnetic cover method, etc. Among them, flotation is the most widely used phosphate rock beneficiation method. process, including direct flotation, reverse flotation, forward and reverse flotation and double reverse flotation.

Phosphate ore flotation production line can be used for phosphate rock with complex and diverse ore structure, complex mineral occurrence relationship, small khenpo particle size, close mosaic relationship, common mixed symbiosis, and difficult monomer dissociation.

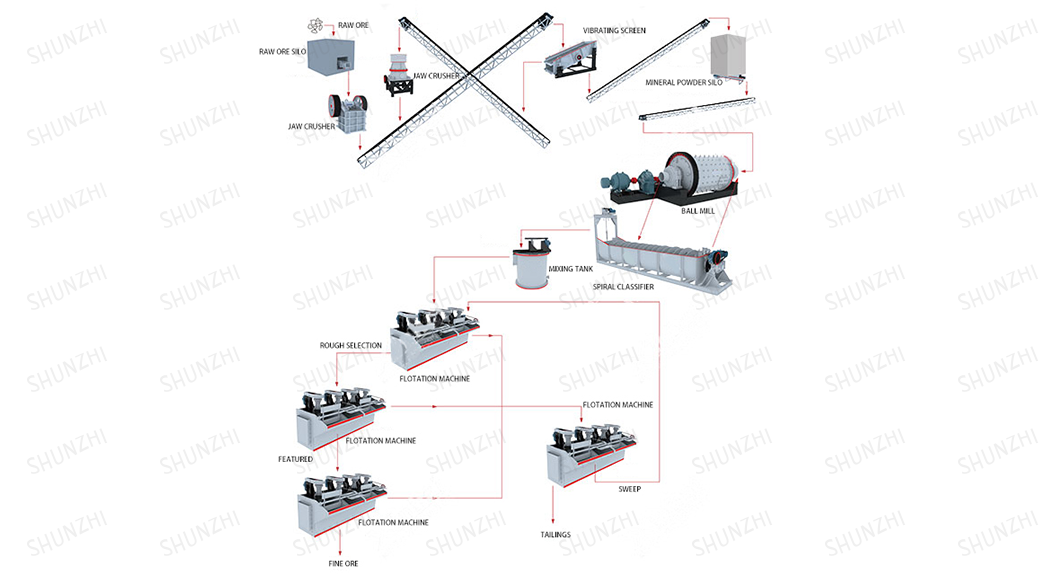

Process method

Due to the complex structure and diverse properties of phosphate rock, the flotation process is a widely used phosphate rock beneficiation process.

Positive flotation process

Direct flotation is the use of effective inhibitors to inhibit gangue minerals, and the use of collectors to enrich phosphorus minerals in foam, which is suitable for low-grade phosphate rock, including magmatic rock type apatite and sedimentary metamorphic apatite. rock ore.

reverse flotation process

It is mainly used for the separation of phosphate rock and dolomite. The fatty acid collector is used to float the dolomite in the weak alkaline medium, and the phosphorus minerals are enriched in the tank. Coarse is conducive to product post-processing.

Double reverse flotation process

Double reverse flotation is to make the silicate surface positively charged and use anionic collectors to separate the target minerals under alkaline conditions, that is, dolomite first, and then reverse flotation silicate, and the product in the tank is For heavy concentrate, the production line can be carried out at normal temperature and with relatively coarse particle size.

1. According to the ore composition, you can freely choose the matching model.

2. The whole system reduces energy consumption and improves recovery rate.

3. Small footprint, convenient operation and higher beneficiation efficiency.

4. The discharge material can reach the standard concentrate index, which is environmentally friendly and pollution-free.